QUALITY OVERVIEW

QUALITY COMMITMENT

Quality is Our First Priority

How does Australian Pipeline Valve (APV) manufacture valves that offer superior performance, reliability and service life? The answer is Total Quality Commitment. Since its founding, APV’s philosophy has been focused on quality. Our valves are manufactured in full compliance to worldwide standards (such as ASME section III, ANSI B16, API6D, API600, API602, API603, API607, ISO, DIN, BS, AS).

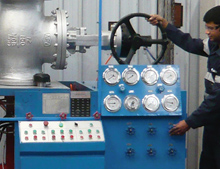

Product Testing

Every APV valve is subjected to hydrostatic testing before leaving the factory to help ensure problems won’t arise in the field.

PRODUCTION PHILOSOPHY

APV products are produced by ISO 9001 certified API licensed subcontractors and partner manufacturers. Product design is managed and reviewed in-house at our Adelaide facility. APV products are produced internationally utilising Australian manufacturing and engineering facilities as well as a well established group of selected accredited manufacturing partners and subcontractors located in Korea, Romania, Taiwan, Italy, USA and China.

COMPANY VISION

• Maintain our position as a centre of excellence in the valve industry

• Our customers needs come first

• Ensure that health, safety, the environment and human dignity are considered of paramount

importance at all times

• Guarantee a cost and time-effective solution

• Ensure on time delivery

• Continually work to improve service, quality and product range

• Continue to develop long term strategic agreements with a reliable, high quality network

of sub-contract manufacturers and suppliers

MISSION STATEMENT

"To continuously improve the level of service and product quality provided to our customers. Superior processes, products, services and solutions will increase customers’ productivity and profits and decrease production downtime. To achieve this employees and customers are treated as partners in our business."

QUALITY PROFILE

APV’s main quality policy is to satisfy the needs and specified requirements of our clients. APV services all major participants in the oil, gas, mining and power generation sectors throughout Australia and most of the southern hemisphere.

Since its inception in 1989, APV has invested in research and development, partnering with

API accredited sub-contractors to produce high quality products in accordance with strict

engineering criteria. This process includes continuous testing, independent inspection and

design improvements to ensure a consistant, high quality product that has enduring performance.

The quality of the valves manufactured is always a priority at APV,

as well as the after sales service.

"Customer Satisfaction is the mission for

Australian Pipeline Valve - no compromises"

APV supplies major participants in the oil, gas,

mining, process industries, water treatment and

power generation sectors throughout Australia

and most of the Southern Hemisphere.

The quality and reliability of APV products

are checked, verified and guaranteed by the

implementation of appropriate quality control

procedures from the incoming raw materials,

contract review, engineering and design, procurement

and production processes to the final acceptance test.

MATERIAL SPECIFICATIONS

All manufactured valves are available for the widest range of applications in temperatures from -196°C to 450°C and in materials such as carbon steel, alloy steel, stainless steel, duplex and super duplex steels, inconel 625, monel K400 and K500, incoloy 825, hastelloy, and titanium. In-house PMI testing can also be optionally performed.

QUALITY CONTROL

APV valves are subject to strict

manufacturing controls and designed and tested to comply

with applicable International standards.

All APV products are tested to ensure they meet all the accepted

standards for Quality Assurance. From PMI and Ultrasonic testing

to Hydrostatic testing for zero leakage and final inspection,

APV works to provide you with the quality you need.

We conduct audits and reviews on a regular basis to verify and maintain the highest levels of product quality as well as documentation, certification, compliance in systems, procedures and processes.

PRESSURE TESTING INSPECTION

AND TESTING ACTIVITIES

APV can manage third party surveys,

reviews and witnessing of any required

non-destructive tests such as:

• X-Rays

• Ultrasonic Tests

• Magnetic Particle Inspection

• Positive Material Identification

• Dye Penetrant Liquid Inspection